SIPS in Vermont are Affordable

Price Competitive

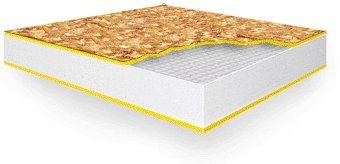

We at Tanguay Homes of Newport, Vermont believe that the panels are, dollar for dollar, a better buy than any other insulation system. The Thermal performance of a building system is the highest concern of consumers today. Our SIPs offer the highest R-value for the lowest possible cost. The R-value of EPS remains stable for the life of the structure, unlike panels using expanded polyurethane, isocyanurate or fiber glass. Our panels require less construction time. The system fits together more quickly, and simply than conventional framing, for an overall savings in man-hours.

Ease of Installation

Simplicity is the key to a successful construction. Structural Insulated Panels

can be installed faster and more easily than stud wall. The double surface spline system with a foam sealing channel makes our system very efficient and simple to install. A three person crew can expect to enclose a simple 200 square foot home in a week or less.

Our SIPs can be cut with inexpensive saws and attached to timbers with annular nails. Windows and doors are installed easily because the panels are designed to accommodate standard building materials. A saw cut is all that is required for the window or door opening.

Manufacturing Flexibility

Tanguay Homes of Newport, Vermont can get Structural Insulated Panels (SIPs) specifically for your building needs, offering a variety of sizes and laminates. Because of this manufacturing flexibility, the basic component can be utilized in residential, commercial and agricultural buildings as a floor, wall or roof component. This gives greater versatility in design, which translates into an overall savings for you.

Environmental Concerns

At Tanguay Homes

of Newport, Vermont, we use EPS (expanded polystyrene) foam cores to give you a product that will serve your needs for years to come. We also recognize the need to produce a product that is safe for the environment.

Other insulation products such as polyurethane use chlorofluorocarbons (CFC’s) in the manufacturing process. These CFC’s are light gases that escape from the polyurethane. This outgassing reduces the R-value of the product and contributes to the depletion of the earth’s ozone layer.

EPS, on the other hand, uses captured air from its thermal properties. For you, this means a product that will maintain its R-value for the life of the home, while giving you peace of mind

, knowing that you have not contributed to harmful ozone depletion.

Find Us Here!

Tanguay Homes, Inc.

419 Route 105 Suite A,

Newport, Vermont 05855

Mailing Address:

P.O. Box 517

Newport, VT 05855

Follow Us!

Tanguay Homes of Newport, Vermont specializes in working with out-of-the-area clients. You may sign up to receive daily progress photos, e-mails, and calls. Weekend and late evening appointments are available for your convenience.

Tony Tanguay

President

Contact Us!

We will get back to you as soon as possible

Please try again later